Quality identification method for groove pipe fittings

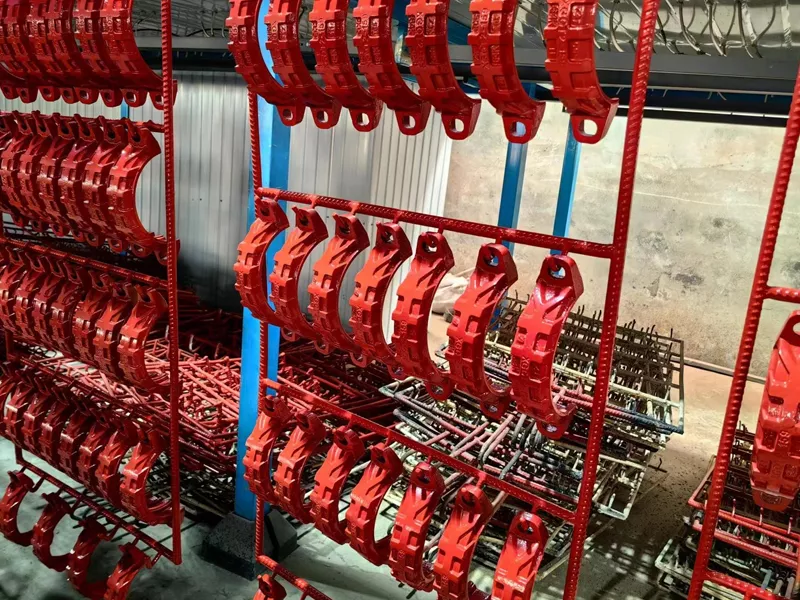

In the pipeline installation of groove fittings, there is an important type of connecting fittings. Groove fittings are classified according to their different functions, such as clamps for connecting purposes, elbows for changing the direction of pipelines, etc. Various groove fittings have great uses, so the sales volume of groove fittings is constantly increasing. How do consumers distinguish the quality when purchasing groove fittings?

The method for identifying the quality of groove fittings is to tap the surface of the groove fitting product by hand and check the toughness of the fitting. If the outer wall of the fitting is forcefully tapped, there will be slight unevenness and deformation on the surface of the fitting, and the overall fitting will not break, which proves that the toughness of the fitting is still good and the performance is excellent.

Observing the thread length and galvanization degree of pipe fittings, generally low-quality pipe fittings have shorter threads. Good pipe fittings have a good layer of galvanization on the surface to prevent pipe decay. Galvanization is carried out by heating and galvanizing before threading processing, while poor quality pipe fittings are threaded and then galvanized, or replaced with other coatings. This method is low-cost but has poor anti-corrosion effect. After pipeline installation, it will rust and affect water quality.

Observing the quality of groove fittings, products with insufficient quality have smaller outer diameters and generally lower weights, which can easily cause problems during use.

Recommended

Application case of grooved pipe fittings in construction industry