What are the similarities and differences between groove fittings and traditional connection techniques

What are the similarities and differences between groove fittings and traditional connection techniques?

In terms of operation, groove fittings require very few facilities and are easy to organize. Traditional pipe connection technology not only involves complex construction, but also poses risks of electrical leakage and fire hazards, as well as problems such as welding slag pollution of pipelines and water quality. This not only greatly reduces water quality, but also shortens the critical service life.

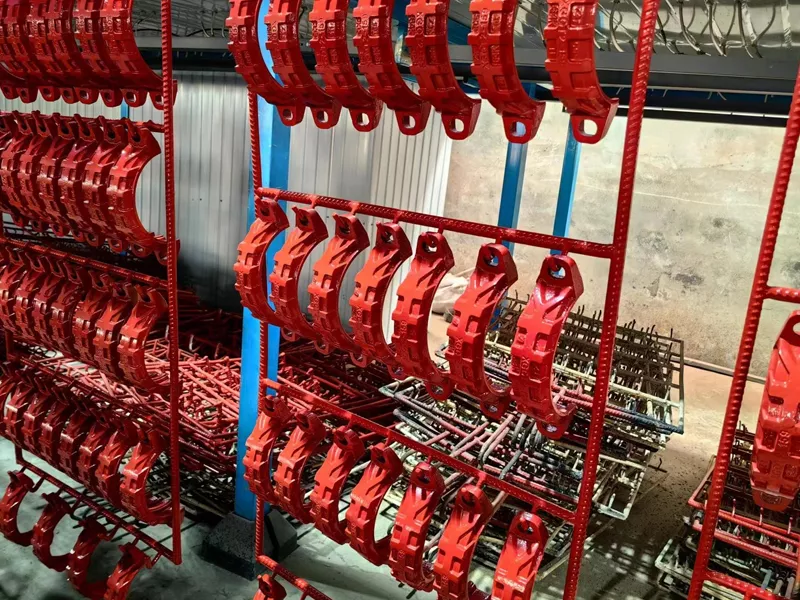

In terms of connection, the connection of groove fittings has special technical advantages. The unique flexibility of groove fittings gives them characteristics such as anti vibration and high stability in pipe connections, which changes the traditional defects of high noise and easy breakage in pipe connections, greatly extending the service life of the fittings, increasing their stability, adapting to temperature changes, and providing protection for other components of the fittings.

In terms of maintenance, the repair of groove fittings is more convenient, which can greatly reduce the time spent on maintenance and has good performance.

Recommended

Application case of grooved pipe fittings in construction industry