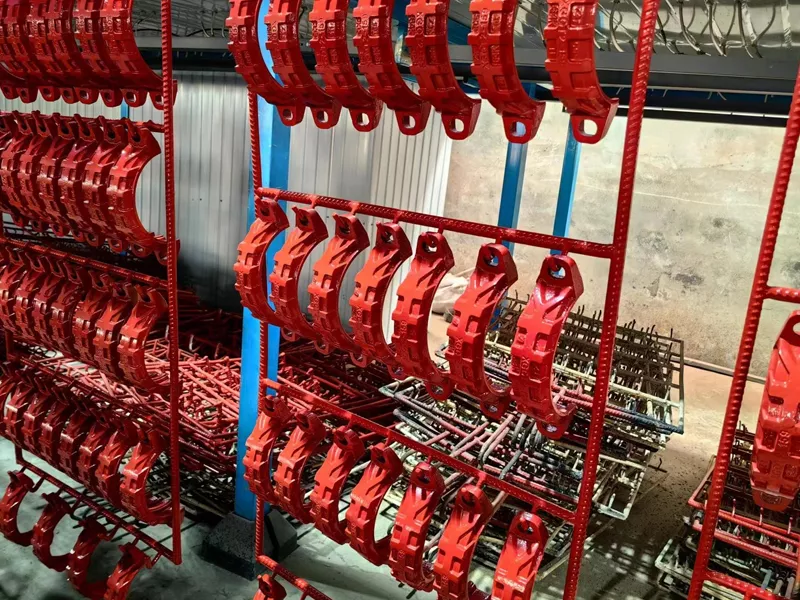

Working principle of grooved pipe fittings

Grooved pipe fittings have become increasingly popular in the plumbing industry due to their ease of installation and versatility. These fittings consist of two components – a grooved pipe and a gasket – that work together to create a secure and leak-proof connection. In this article, we will explore the working principle of grooved pipe fittings and how they are used in various applications.

The key to the effectiveness of grooved pipe fittings lies in the unique design of the grooves on the pipe and the gasket. The grooves are typically machined into the pipe using a specialized tool, creating a series of ridges that run along the length of the pipe. The gasket, which is made of a flexible material such as rubber or EPDM, is then placed over the grooves on the pipe.

When the two components are fitted together, the gasket is compressed between the grooves on the pipe, creating a tight seal that prevents leaks. The pressure from the fluid inside the pipe further compresses the gasket, ensuring a secure connection. This design allows grooved pipe fittings to withstand high pressures and temperature fluctuations without compromising their integrity.

One of the main advantages of grooved pipe fittings is their ease of installation. Unlike traditional threaded or welded fittings, grooved fittings can be assembled quickly and without the need for specialized tools or equipment. The grooves on the pipe act as a guide for positioning the gasket, making it easy to align the components and create a tight seal.

Grooved pipe fittings are also highly versatile and can be used in a wide range of applications, including water supply systems, fire protection systems, and HVAC systems. They are commonly used in commercial and industrial buildings where reliability and efficiency are paramount. The ability to easily disassemble and reassemble grooved fittings makes them ideal for applications that require frequent maintenance or modifications.

In addition to their ease of installation, grooved pipe fittings are also cost-effective. The simple design of these fittings reduces labor costs associated with installation, while the durable materials used in their construction ensure long-term reliability. Grooved fittings require minimal maintenance and are resistant to corrosion, making them a cost-effective solution for a variety of plumbing projects.

Overall, the working principle of grooved pipe fittings is based on the tight seal created by the compression of the gasket between the grooves on the pipe. This design allows for quick and easy installation, high pressure resistance, and cost-effective operation. Grooved fittings are a versatile solution for a wide range of plumbing applications and offer numerous benefits compared to traditional fittings.

Recommended

Application case of grooved pipe fittings in construction industry